7 Best Vacuum Molding Techniques to Elevate Your Manufacturing Process

In the competitive landscape of manufacturing, achieving efficiency and precision is paramount, and vacuum molding has emerged as a transformative technique that can elevate production processes to new heights.

This innovative method utilizes atmospheric pressure to shape materials into intricate and high-quality forms, making it a preferred choice for a variety of industries.

By exploring the seven best vacuum molding techniques, manufacturers can optimize their workflows, reduce costs, and enhance product quality.

From the selection of materials to the intricacies of the molding process itself, understanding these techniques is essential for businesses looking to stay ahead of the curve.

As technology continues to evolve, vacuum molding not only offers a sustainable approach to manufacturing but also opens up endless possibilities for creativity and customization.

Embracing these strategies is crucial for any organization aiming to refine their manufacturing processes and deliver exceptional products.

This innovative method utilizes atmospheric pressure to shape materials into intricate and high-quality forms, making it a preferred choice for a variety of industries.

By exploring the seven best vacuum molding techniques, manufacturers can optimize their workflows, reduce costs, and enhance product quality.

From the selection of materials to the intricacies of the molding process itself, understanding these techniques is essential for businesses looking to stay ahead of the curve.

As technology continues to evolve, vacuum molding not only offers a sustainable approach to manufacturing but also opens up endless possibilities for creativity and customization.

Embracing these strategies is crucial for any organization aiming to refine their manufacturing processes and deliver exceptional products.

Latest Innovations in Vacuum Molding Techniques for Enhanced Production

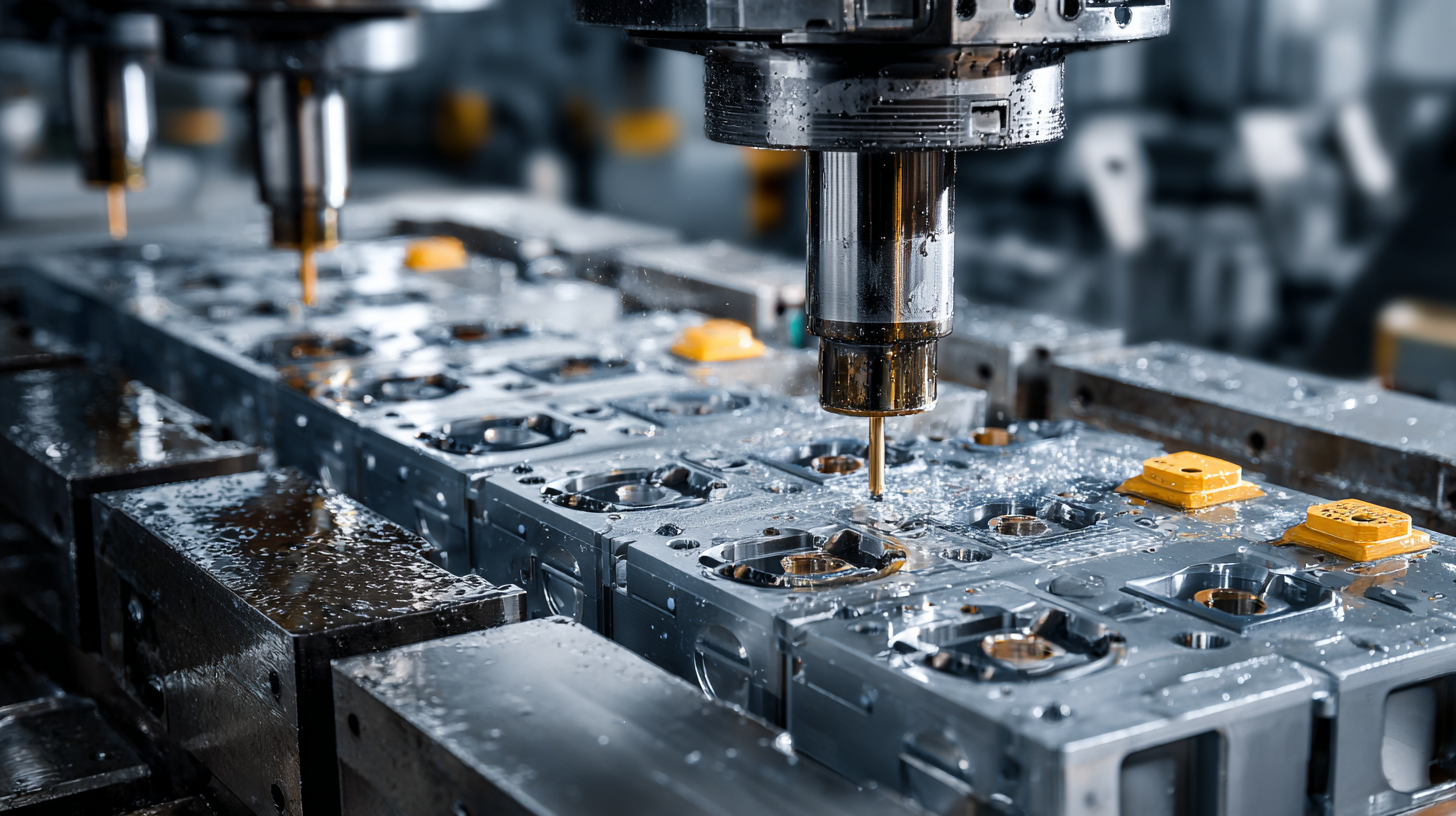

Recent advancements in vacuum molding techniques have significantly enhanced the production capabilities of various industries. One of the most notable innovations is the integration of advanced materials such as thermoplastics and composite resins, which not only improve the durability of the molded products but also expand design possibilities. These materials allow for the creation of lightweight yet strong components, making them ideal for applications in automotive, aerospace, and consumer goods.

Moreover, the automation of vacuum molding processes through robotics and smart technology has led to improved efficiency and precision. Automated systems can accurately control parameters such as temperature and pressure, resulting in consistent quality and reduced waste. Additionally, the implementation of real-time monitoring systems allows manufacturers to identify and address issues promptly, thus minimizing downtime. The combination of these innovations is paving the way for a more streamlined production environment, where companies can adapt quickly to market demands while maintaining high standards of quality and sustainability.

Comparative Analysis of Traditional vs. Modern Vacuum Molding Methods

The comparative analysis of traditional versus modern vacuum molding methods highlights significant advancements that can enhance manufacturing processes. Traditional vacuum molding relies heavily on manual techniques which often result in inefficiencies and variability in product quality. According to industry reports, this method can lead to a waste rate of approximately 10-15%, primarily due to human errors and material limitations.

In contrast, modern vacuum molding technologies integrate automation and advanced materials which significantly reduce production waste and optimize efficiency. For instance, the use of high-temperature vacuum-assisted resin transfer molding has demonstrated a reduction in void contents and thickness variation, enhancing the overall quality of the final product.

In contrast, modern vacuum molding technologies integrate automation and advanced materials which significantly reduce production waste and optimize efficiency. For instance, the use of high-temperature vacuum-assisted resin transfer molding has demonstrated a reduction in void contents and thickness variation, enhancing the overall quality of the final product.

Furthermore, the trend towards integrating sustainable practices in manufacturing is evident within modern vacuum molding techniques. The incorporation of bioplastics and recycled materials is becoming more prevalent. Research indicates that using composite materials derived from renewable resources can decrease the carbon footprint associated with conventional plastics by up to 40%. This shift not only caters to the increasing demand for eco-friendly products but also aligns with the broader industry movement toward sustainability. Hence, companies that adapt to these modern techniques are better positioned to meet market demands while simultaneously contributing to environmental conservation.

Key Benefits of Vacuum Molding in Streamlining Manufacturing Processes

Vacuum molding is a transformative technique that significantly enhances manufacturing processes by offering a range of benefits. One of the primary advantages of vacuum molding is its ability to produce lightweight and durable components. This is particularly valuable in industries such as automotive and aerospace, where reducing weight can lead to improved fuel efficiency and performance.

The precision of vacuum molding also ensures higher accuracy in shaping complex designs, allowing manufacturers to create intricate components without sacrificing structural integrity.

By integrating vacuum molding techniques, companies can not only enhance product quality but also gain a competitive edge in the ever-evolving manufacturing landscape.

Step-by-Step Guide to Implementing Vacuum Molding in Your Workflow

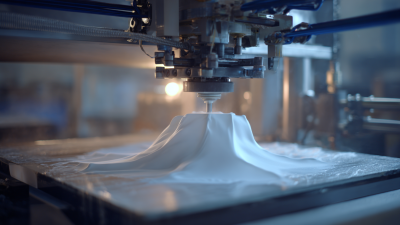

Vacuum molding is an efficient and precise manufacturing technique that can significantly enhance your production workflow. To successfully implement this method, start by selecting the right materials. Choose thermoplastics that meet your requirements for strength and flexibility. Once your materials are in place, prepare your molds with precision to ensure that they can withstand the pressure of vacuum forming while maintaining the desired shape and finish.

**Tips:** Always test your mold designs at a smaller scale before full production. This will help identify any potential issues without the risk of larger material waste. Additionally, it's crucial to maintain a clean working environment to avoid contamination that can affect the final product’s quality.

After securing the right materials and preparing your molds, it's time to optimize your machine settings. Ensure that the temperature and pressure are adjusted according to the specifics of the materials you're using. Regular maintenance of equipment is essential; keep your vacuum pump and heating elements in top condition to ensure consistent performance across all production runs.

**Tips:** Document your machine settings and adjustments for each project, creating a reference guide that will help streamline future operations. This practice can also lead to better troubleshooting and adjustments when necessary.

Future Trends: What’s Next for Vacuum Molding Technologies in Manufacturing

Vacuum molding has evolved significantly over the years, and future trends suggest a remarkable shift toward enhanced efficiency and sustainability in manufacturing processes. The integration of advanced materials, such as bio-based plastics and lightweight composites, is becoming increasingly prevalent. These materials not only contribute to lower overall production costs but also align with the growing demand for environmentally friendly practices in the industry. As manufacturers seek to minimize their carbon footprint, the adoption of such eco-friendly materials is expected to lead to innovative solutions in vacuum molding technology.

Moreover, the advent of smart manufacturing technologies, including IoT and automation, is poised to transform vacuum molding operations. Implementing real-time data analytics and machine learning algorithms can lead to improved process control, enhanced precision, and reduced cycle times. These advancements are likely to optimize resource utilization and minimize waste, significantly improving overall efficiency. As manufacturers continue to embrace digital transformation, vacuum molding techniques will evolve, paving the way for more agile production systems that can adapt quickly to market demands and create custom solutions for diverse applications.

Related Posts

-

Understanding the Excellence of the Best CNC Machine Available

-

The Future of Vacuum Forming Machine Technology: Innovations Transforming Manufacturing

-

How to Choose the Right Containment Tray for Your Industrial Needs

-

10 Essential Tips for Sourcing the Best Plastic Drip Tray for Your Business Needs

-

Unmatched Quality in Plastic Spill Trays from China Leading the Global Market

-

7 Essential Tips for Mastering Vacuum Forming in Your Production Process