7 Essential Tips for Mastering Vacuum Forming in Your Production Process

Vacuum forming has emerged as a pivotal technique in the manufacturing sector, particularly for industries ranging from automotive to consumer products. According to a report by MarketsandMarkets, the global vacuum forming market is projected to reach USD 4.02 billion by 2025, growing at a CAGR of 5.5%. This growth underscores the technique's increasing relevance in producing lightweight, cost-effective components with precision. As manufacturers strive to streamline production processes and enhance product quality, mastering vacuum forming becomes essential. Understanding its intricacies not only fosters efficiency but also supports innovation in design and functionality.

In this blog, we will explore seven essential tips that can help you successfully incorporate vacuum forming into your production protocols, ensuring that you stay competitive in today’s fast-evolving marketplace.

Understanding the Basics of Vacuum Forming for Beginners

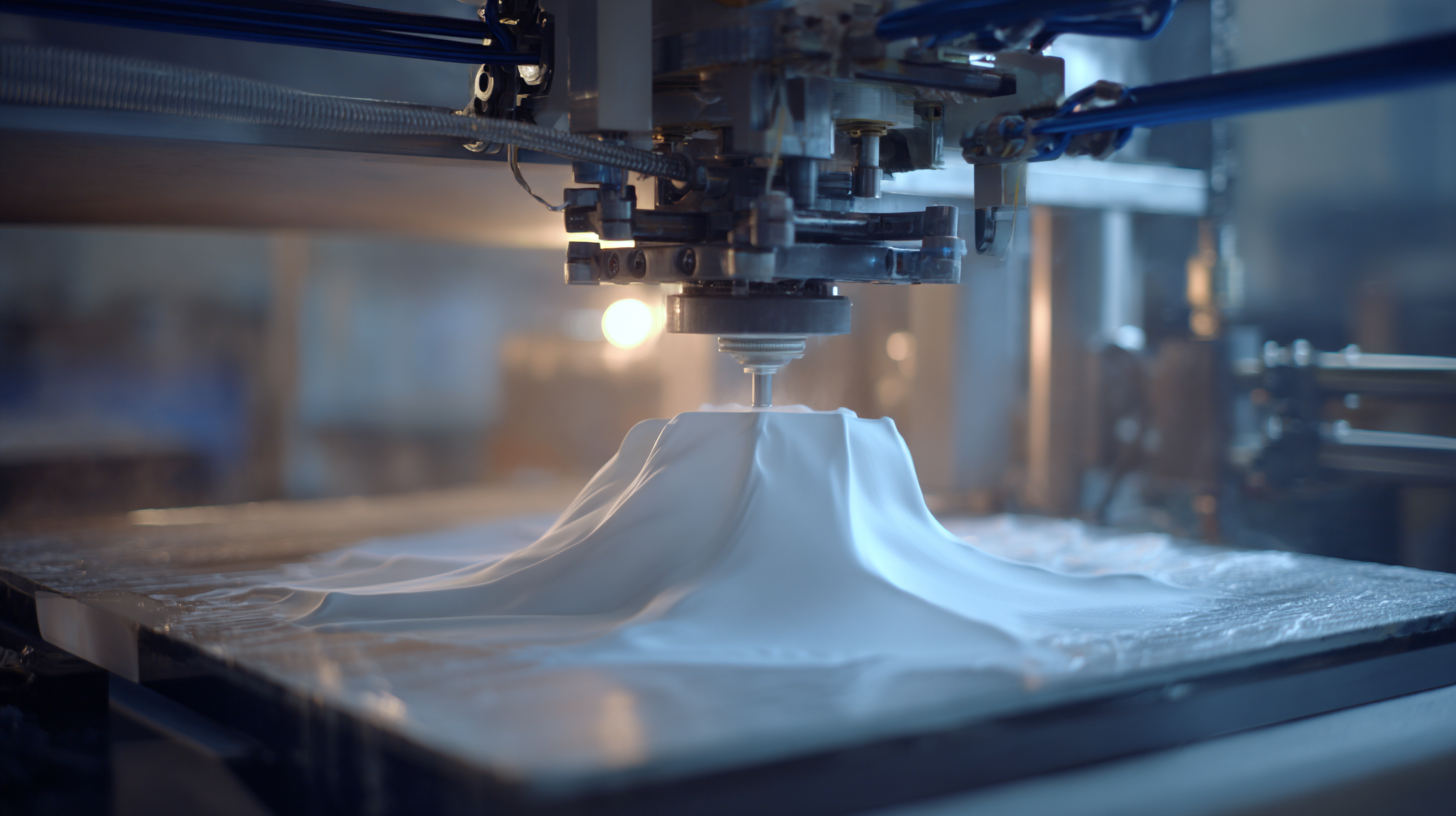

Vacuum forming is an essential process in manufacturing that transforms plastic sheets into intricate shapes using suction. For beginners, understanding the basics is crucial to mastering this technique. The process begins with heating a thermoplastic sheet until it becomes pliable. After reaching the desired temperature, the sheet is placed over a mold and vacuum pressure is applied, drawing the plastic tightly against the mold. This straightforward yet effective method allows for the creation of various products, from packaging materials to automotive components.

To excel in vacuum forming, one key tip is to ensure proper temperature control. Different plastics require specific heating temperatures, and overheating can lead to deformation or inconsistencies. Additionally, using a high-quality mold is vital; a smooth, well-designed mold will yield better results and reduce the likelihood of defects. Another important aspect is to maintain consistent vacuum pressure during the forming process, which helps achieve uniformity in the final product, minimizing the risk of air bubbles or wrinkling. By keeping these fundamentals in mind, beginners can develop a strong foundation in vacuum forming and enhance their production processes.

Key Materials Needed for Effective Vacuum Forming

When it comes to mastering vacuum forming, choosing the right materials is crucial for achieving optimal results in your production process. The effectiveness of vacuum forming largely depends on the plastic sheet materials you select. Commonly used materials include ABS, PVC, and PETG, each offering distinct advantages. For instance, ABS is known for its excellent impact resistance and ease of machining, making it ideal for a variety of applications. Meanwhile, PVC offers good chemical resistance and flexibility, suitable for projects requiring durability and formability.

Additionally, the thickness of your plastic sheet plays a vital role in determining the final product's strength and quality. Thinner sheets are easier to form but may not provide the same level of durability. Conversely, thicker materials can enhance strength but may complicate the forming process. Therefore, striking a balance based on your specific requirements is essential. Furthermore, consider experimenting with different surface finishes, as they can greatly affect the aesthetics and functionality of the finished product. By understanding these key materials and their characteristics, you can optimize your vacuum forming process for superior outcomes.

7 Essential Tips for Mastering Vacuum Forming in Your Production Process - Key Materials Needed for Effective Vacuum Forming

| Material Type | Properties | Typical Applications | Thickness Range (mm) |

|---|---|---|---|

| Acrylic (PMMA) | Clear, High Impact Resistance, UV Resistant | Display Cases, Light Covers, Signage | 1.5 - 6.0 |

| Polycarbonate (PC) | High Impact Strength, Excellent Clarity, Flame Resistant | Safety Shields, Machine Guards, Optical Lenses | 2.0 - 8.0 |

| PETG | Easy to Form, Low Shrinkage, Good Chemical Resistance | Protective Covers, Blister Packs, Medical Devices | 0.5 - 6.0 |

| HIPS | Good Impact Resistance, Lightweight, Cost-effective | Toys, Containers, Interior Panels | 1.0 - 5.0 |

| PVC | Durable, Chemical Resistant, Versatile | Signage, Packaging, Construction Materials | 1.0 - 5.0 |

| ABS | High Strength, Good Heat Resistance, Easy to Paint | Automotive Parts, Household Items, Electronic Housings | 1.0 - 5.0 |

Step-by-Step Guide to Setting Up Your Vacuum Forming Machine

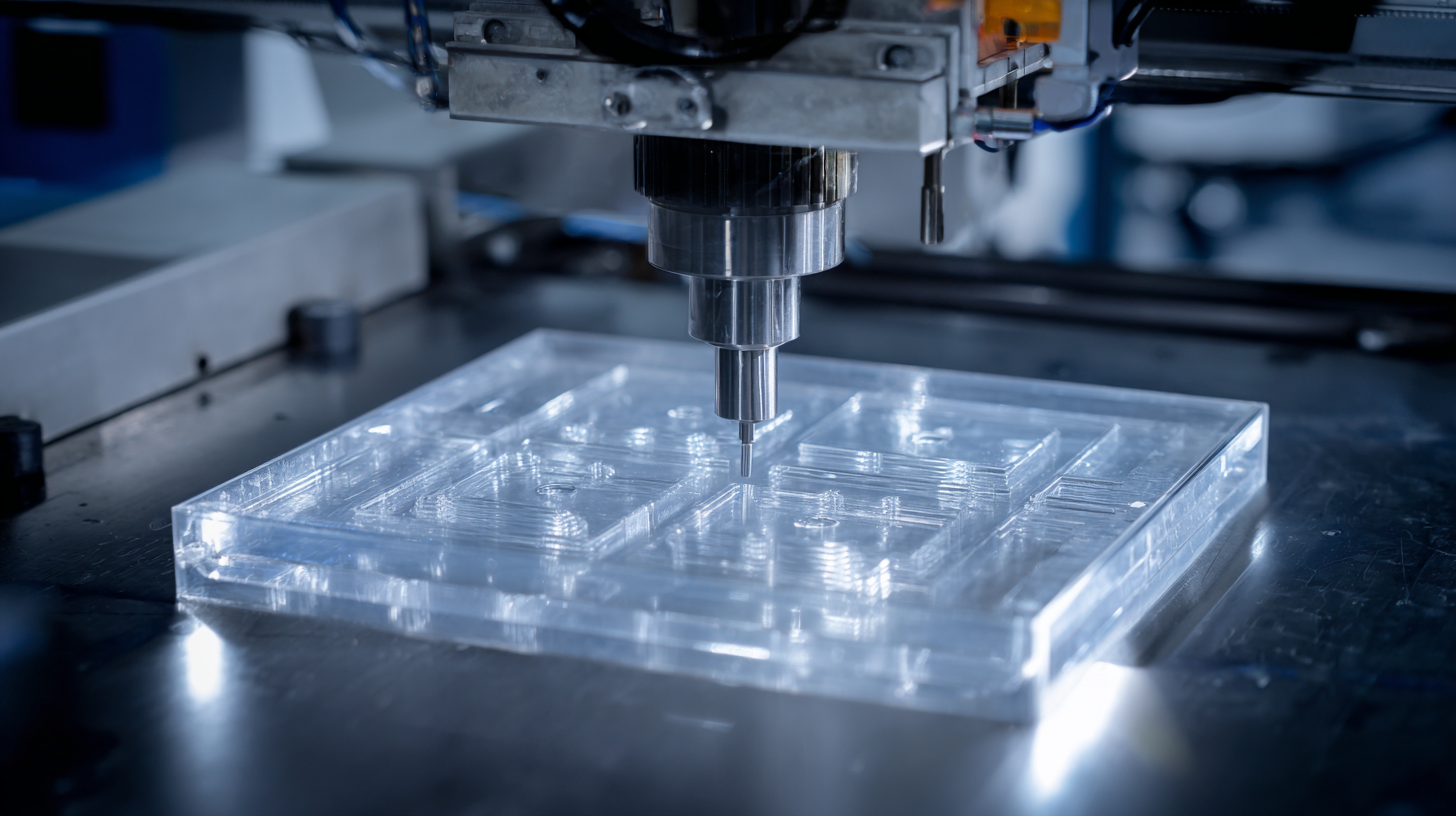

Setting up your vacuum forming machine is a crucial step in ensuring a smooth production process. Begin by selecting a suitable mold that perfectly matches the design requirements. The materials for the mold can range from wood to metal, depending on factors like durability and detail. Once your mold is ready, secure it to the machine’s bed to prevent any movement during the forming process. It is essential to check that all components are tightly fitted, including the heating elements, to ensure optimal performance.

Next, prepare your thermoplastic sheet by cutting it to the appropriate dimensions, allowing enough material to cover the mold. Place the sheet in the heating area, and monitor the temperature closely to avoid overheating, which could lead to deformation. Once the sheet reaches the desired softness, activate the vacuum to pull the material over the mold. Monitor the process to ensure the plastic conforms correctly without trapping air bubbles, which can compromise the final product. By following these steps meticulously, you’ll be on your way to mastering the art of vacuum forming.

Common Mistakes to Avoid in the Vacuum Forming Process

When diving into the vacuum forming process, avoiding common pitfalls is essential for a smooth production journey.

One major mistake is not properly preparing the mold. A poorly designed mold can lead to inconsistent thickness and surface defects in the final product. Ensuring that the mold is smooth, durable, and correctly sized will contribute significantly to the quality of the formed items.

Another common error occurs when choosing the wrong type of plastic material. Different materials can behave uniquely under heat and pressure; selecting the incorrect plastic can result in warping or breaking.

It's crucial to match the material properties, such as melting temperature and rigidity, to the specific requirements of your project.

Additionally, operators should be aware of the temperature and timing during the forming process; insufficient heating can prevent proper forming, while overheating can ruin the material.

By addressing these issues, manufacturers can enhance their efficiency and product quality in vacuum forming.

Tips for Optimizing Product Design for Vacuum Forming Success

Optimizing product design for vacuum forming success is crucial in today's manufacturing landscape, especially as industries increasingly seek sustainable practices. Incorporating new technologies like AI and the Industrial Internet of Things can lead to significant enhancements in resource efficiency. A recent study highlights the convergence of lean management and additive manufacturing as a way to minimize waste, creating more sustainable processes. For vacuum forming, this means designing products that not only meet aesthetic and functional needs but also utilize materials strategically for minimal waste during production.

Additionally, it’s essential to consider the scalability of your design for wider market applicability. As reported, companies integrating advanced technologies are better positioned to adapt to the circular economy principles, which emphasize product lifecycles and resource efficiency. By utilizing insights from supply chain management and advanced analytics, businesses can refine their product designs to align with both market demands and sustainability goals. This holistic approach ensures that vacuum-formed products not only succeed in design but also contribute to a more sustainable manufacturing ecosystem.

Related Posts

-

How to Choose the Best Vacuum Forming Machine for Your Business Needs

-

Understanding the Process of Vacuum Forming Plastic: A Beginner's Guide

-

Exploring Innovative Alternatives to Traditional Vacuum Molding Machine Solutions

-

Ultimate Guide to Choosing the Best Spill Tray for Chemicals Based on Your Needs

-

Innovative Chinese Manufacturing Elevates Global Sales of Top Thermoforming Vacuum Machines

-

Unmatched Quality in Plastic Spill Trays from China Leading the Global Market