Exploring Innovative Alternatives to Traditional Vacuum Molding Machine Solutions

In the realm of manufacturing and prototyping, the vacuum molding machine has long stood as a reliable solution for producing high-quality parts with intricate designs. However, as industries evolve and demand for more efficient and sustainable practices grows, traditional vacuum molding machines are facing challenges that necessitate innovation. This blog delves into the exploration of groundbreaking alternatives to conventional vacuum molding machine solutions, examining various examples that leverage new technologies and methodologies to enhance performance, reduce costs, and minimize environmental impact. By evaluating these innovative approaches, we aim to highlight the potential of modern advancements in vacuum molding and inspire manufacturers to rethink their production strategies to stay competitive in today's dynamic market.

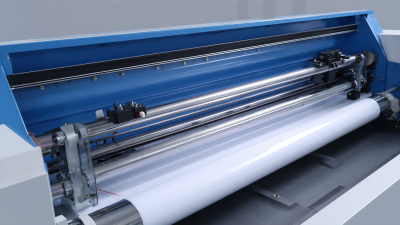

Emerging Technologies Revolutionizing Vacuum Molding Processes

As industries seek more efficient manufacturing processes, innovative technologies are emerging to revolutionize traditional vacuum molding. Advanced materials, such as thermoplastics and bio-based resins, are enhancing product durability and reducing environmental impact. Additionally, the integration of automation and robotics into vacuum molding processes increases precision and reduces labor costs. These technologies not only streamline production but also allow for customization, meeting the diverse demands of modern consumers.

Tip: When exploring alternatives to traditional vacuum molding, consider implementing 3D printing techniques. This can dramatically speed up the prototyping phase, allowing for rapid iterations and a better final product.

Another exciting development is the use of AI in monitoring and controlling the molding process. By applying machine learning algorithms, manufacturers can optimize parameters in real-time, leading to improved quality and reduced waste. This holistic approach ensures that every aspect of the vacuum molding process benefits from cutting-edge technology.

Tip: Ensure your team is trained in these new technologies. Investing in staff education will maximize the potential of innovative tools, ultimately giving your manufacturing processes a competitive edge.

Sustainable Materials: Eco-Friendly Alternatives to Traditional Molding

As the demand for sustainable production methods grows, the molding industry is witnessing a significant shift towards eco-friendly alternatives to traditional vacuum molding materials. Traditional molding often relies on synthetic materials that contribute to environmental degradation, prompting manufacturers to explore new biodegradable and recyclable options. These sustainable materials not only reduce the ecological footprint but also meet the rising consumer demand for greener products.

Innovative alternatives such as bio-based plastics, plant fibers, and recycled composites are gaining traction in the molding process. Bio-based plastics, derived from renewable resources like cornstarch or sugarcane, offer similar performance characteristics to their petroleum-based counterparts while significantly lowering carbon emissions. Additionally, incorporating natural fibers like hemp or flax into molding solutions can enhance strength and reduce waste, as these materials are biodegradable and sourced from sustainable agriculture. This shift not only benefits the environment but also opens up new possibilities for product design and functionality, demonstrating that sustainability and quality can go hand in hand.

Comparative Analysis of Cost-Effective Vacuum Molding Solutions

The evolution of vacuum molding technologies has paved the way for cost-effective solutions that challenge traditional methods. This comparative analysis delves into innovative alternatives that optimize both the performance and economic viability of vacuum molding processes. By exploring advancements such as lightweight materials and energy-efficient systems, manufacturers are now able to produce high-quality components at reduced costs. These innovations not only enhance production efficiency but also minimize environmental impact, making them especially appealing in today's sustainable-oriented market.

One notable trend is the integration of digital technologies into the vacuum molding process. Techniques like 3D printing and automation are increasingly being adopted, allowing for greater customization and faster turnaround times. Additionally, the shift towards using sustainable materials in mold design is reshaping the industry landscape. This convergence of technology and sustainability fosters a new era where traditional vacuum molding machines are complemented, if not replaced, by more versatile and eco-friendly alternatives. As the industry continues to embrace these cost-effective solutions, we can anticipate a significant transformation in manufacturing practices across various sectors.

Exploring Innovative Alternatives to Traditional Vacuum Molding Machine Solutions - Comparative Analysis of Cost-Effective Vacuum Molding Solutions

| Solution Type | Initial Cost (USD) | Operational Cost (USD/year) | Production Speed (units/hour) | Material Compatibility | Maintenance Cost (USD/year) |

|---|---|---|---|---|---|

| Traditional Vacuum Molding | $50,000 | $5,000 | 10 | Plastics, Composites | $2,000 |

| Hybrid Vacuum Molding | $40,000 | $4,000 | 15 | Plastics, Metals | $1,500 |

| Digital Vacuum Forming | $30,000 | $3,500 | 20 | Plastics, Composites, Films | $1,000 |

| Vacuum Casting | $25,000 | $2,500 | 8 | Metals, Composites | $1,200 |

| 3D Printing with Vacuum System | $20,000 | $2,200 | 25 | Plastics, Composites | $800 |

Innovations in Automation: Enhancing Efficiency in Molding Machines

In the realm of vacuum molding, automation is transforming traditional processes, allowing manufacturers to enhance efficiency and precision while minimizing waste. By integrating advanced technologies such as robotics and artificial intelligence into molding machines, businesses are not only streamlining operations but also increasing production rates. These innovations enable real-time monitoring and adjustments, ensuring consistent quality in molded products.

Tips for leveraging these automation advancements include investing in reliable robotic systems that can easily interface with existing machines, enabling seamless upgrades without extensive overhauls. Consider incorporating predictive maintenance tools that utilize AI algorithms to analyze machine performance, thereby reducing downtime and improving overall productivity. Additionally, training your workforce to operate and troubleshoot these advanced systems can maximize the benefits of automation, fostering a knowledgeable team that can effectively enhance molding operations.

Furthermore, exploring flexible automation options allows businesses to quickly adapt to changing market demands. Implementing modular equipment enables companies to switch between different production lines without significant financial investment, which is crucial in today's fast-paced manufacturing environment. By prioritizing automation and innovation, companies can stay ahead of the curve and remain competitive in the evolving landscape of vacuum molding.

Innovations in Automation: Efficiency in Molding Machines

This chart illustrates the efficiency improvement in traditional vacuum molding machines versus innovative automated solutions over a three-year period.

Assessing Performance: Traditional vs. Alternative Molding Techniques

In the realm of molding techniques, the performance of traditional vacuum molding machines is frequently contrasted with innovative alternatives that prioritize sustainability. One significant contender is metal injection molding (MIM), recognized for its efficiency and reduced environmental impact. MIM presents a viable green production technology, effectively addressing the mounting concerns over traditional methods that often contribute to pollution and excessive waste. As the industry grapples with environmental challenges, MIM stands out for its ability to utilize materials more judiciously, thereby minimizing resource depletion.

Another emerging alternative worth exploring is the use of bioplastics, derived from renewable natural resources. These materials are rapidly gaining traction as eco-friendly substitutes for traditional plastics, particularly in the food packaging sector. By offering a reduced carbon footprint, bioplastics embody the principles of a circular economy, promoting sustainability without compromising functionality.

This shift signifies a transformative trend in molding techniques, where the integration of sustainable practices becomes paramount. As innovative technologies evolve, the dichotomy between traditional and alternate molding methods becomes increasingly pronounced, making it crucial for industries to reassess their production strategies in light of environmental stewardship.

Related Posts

-

How to Choose the Best Vacuum Forming Machine for Your Business Needs

-

Understanding the Excellence of the Best CNC Machine Available

-

Innovative Chinese Manufacturing Elevates Global Sales of Top Thermoforming Vacuum Machines

-

5 Reasons Why CNC Machine Tooling is Essential for Modern Manufacturing

-

Exploring the Future of CNC Machines in 2025 and Their Unmatched Advantages for Global Buyers

-

Exploring the Top Features of the Best Large Drain Pan for Global Buyers